Mosaic Announces 2024 EHS Risk Reduction Award Recipients

Mosaic Announces 2024 EHS Risk Reduction Award Recipients

Recognizing Outstanding Efforts in Risk Reduction

May 15, 2025

At Mosaic, reducing risk isn’t just a goal—it’s the way we work. Through our EHS Risk Reduction program, we empower employees to lead innovative projects that improve safety, minimize environmental impact, and support our long-term Sustainability Targets.

In 2024, our teams completed over 340 risk reduction projects—bringing our total to more than 4,600 since the program’s inception in 2019. Today, we’re proud to highlight eight projects that stood out across Safety, Environmental, Health, and Sustainability categories, showing what’s possible when people are empowered to lead meaningful change.

Safety Category

(Small Site)

Uberaba 2 – Big Bag Loading Automation

Loading Big Bags onto trucks required employees to climb into truck beds and work beneath silos, creating serious fall and line-of-fire risks. Manual handling also posed ergonomic challenges. As a result, a fully autonomous system was developed to automate the Big Bag loading process, removing the need for workers to enter trucks or perform repetitive lifting.

Project Highlights:

- Eliminated work at heights and line-of-fire risks

- Removed ergonomic hazards

- Plans to expand to other sites (Sorriso and Palmeirante)

.jpg)

(Large Site)

Fospar – Underwater Inspections with a Remotely Operated Vehicle

To maintain structural integrity, Fospar must regularly inspect 131 underwater pier support pillars. This previously required divers to operate in hazardous conditions, risking injury from marine life, rough seas, and potential medical emergencies. The team developed a remotely operated underwater vehicle (ROV), which now performs inspections, capturing video and generating reports—eliminating the need for human divers.

Project Highlights:

- Eliminated diver exposure to underwater hazards

- Reduced the need for support boats and specialized equipment

- Improved safety while maintaining inspection accuracy

.jpg)

Environmental Category

(Small Site)

Rio Verde – Organic Waste Compostin

Without a local landfill, Rio Verde had to transport cafeteria waste 100 miles twice weekly. This created high costs and environmental risks due to potential spoilage and improper handling. The team introduced a composting system to process organic waste on-site, converting it into fertilizer and water for irrigation.

Project Highlights:

- Created 105 lbs of fertilizer and 1,370 gallons of water for site use

- Cost savings of $26,000/year with an 8-month ROI

- Engaged the local community by donating excess compost

(Large Site)

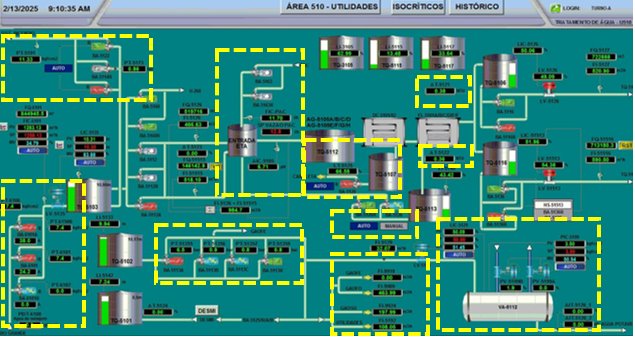

Uberaba 3 – Automation at the Water Treatment Plant

Unreliable demineralization processes led to excess use of water, acid, and lime, creating environmental liabilities and exposing workers to hazardous materials. The plant installed advanced controls and instrumentation to automate operations and optimize chemical use.

Project Highlights:

- Reduced freshwater usage and wastewater discharge

- Cut 455 tons of CO₂ emissions

- Improved reliability and reduced employee exposure to chemicals

- $250,000+ in annual cost savings

Health Category

(Small Site)

Paranaguá – Mechanized Big Bag Unloading

Workers manually carried Big Bag packages over long distances, leading to ergonomic strain.

Collaborating with the supplier, the site switched to palletized delivery and unloading via wheel loader.

Project Highlights:

- Eliminated lifting-related strain

- Cut unloading time from 90 minutes to just 20

(Large Site)

Capital Team at Uberaba 3 – Robotic Welding System

Hot work inside a confined sulfur tank put workers at risk from fumes, heat, and confined spaces. A robotic welding system was introduced to perform linear welds without the need for human entry.

Project Highlights:

- Reduced 1,320 hours of hot work

- Decreased exposure to fumes and ergonomic risks

- Reduced rework rate to under 1%

Sustainability Category

(Small Site)

Uberaba 2 – New Access Route to Distribution Unit

Frequent diesel-fueled truck trips between external warehouses and distribution facilities led to unnecessary CO₂ emissions and traffic on public roads. So, the team developed a secure internal road system, reducing travel distance and emissions while enhancing control and efficiency.

Project Highlights:

- Estimated 24.6-ton CO₂ emissions reduction (2025)

- Saved 23,000 liters of diesel

- Cut public road trips by 16,000 annually

- Reduced freight costs by 21%

(Large Site)

Uberaba 3 – Reducing Limestone in Water Treatment

Excess use of limestone in water treatment processes contributed to increased greenhouse gas emissions and operational inefficiencies. Through process optimization, the team reduced limestone consumption, leading to improved sustainability outcomes.

Project Highlights:

- Reduced emissions

- Supported water and chemical conservation goals

- Reinforced Mosaic’s sustainability commitment

These projects are more than technical achievements—they reflect the innovation, problem-solving, and commitment of our employees around the world. As we continue our journey toward zero incidents and greater sustainability, we’re proud of the difference our teams are making every day. Congratulations to all the 2024 EHS Process Excellence Award recipients!